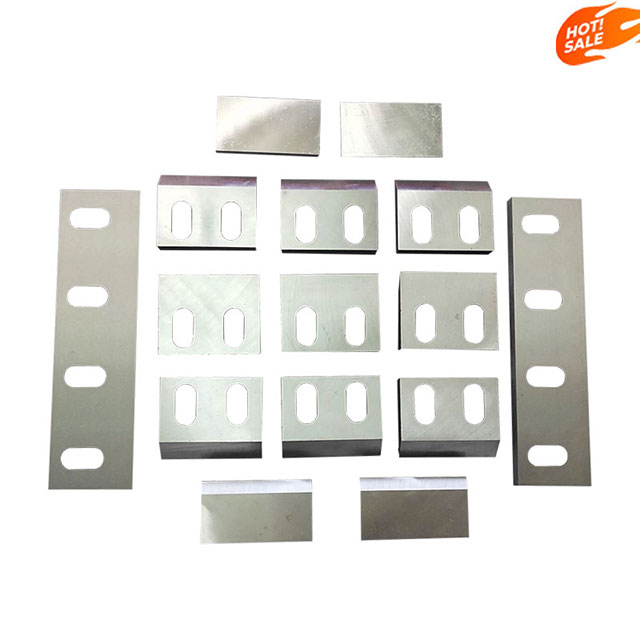

Primarily made of alloy steel, these blades undergo a special heat treatment process, resulting in high hardness and strong wear resistance. Specific features are as follows:

Material and Craftsmanship

The blades are typically made of alloy steel and, after specialized heat treatment, achieve a hardness of HRC 55-58°, ensuring a sharp edge and excellent wear resistance. The surface treatment utilizes a mirror finish for a smooth, even cut.

Construction and Durability

Blade thickness typically ranges from 2-20mm, with single- or double-edged blades. Double-edged blades are particularly suitable for cutting hard or frozen materials. Blades require regular sharpening and replacement. Under normal operation, the fly blade should be sharpened every 4-8 hours, and the bed blade should be replaced every two weeks.

Applications

Suitable for applications such as wood processing and industrial waste shredding, handling materials of varying hardness. The blade’s tip angle (e.g., 80°) balances impact resistance and cutting stability, making it suitable for heavy-duty cutting.