Construction: Utilizing a three-layer progressive fine grinding process, the blade edge roughness is controlled within Ra0.2μm, ensuring cutting accuracy.

Material: Commonly used carbide or ceramic materials, the blade boasts a wear resistance 5-8 times greater than ordinary alloy blades, making it suitable for high-intensity production environments.

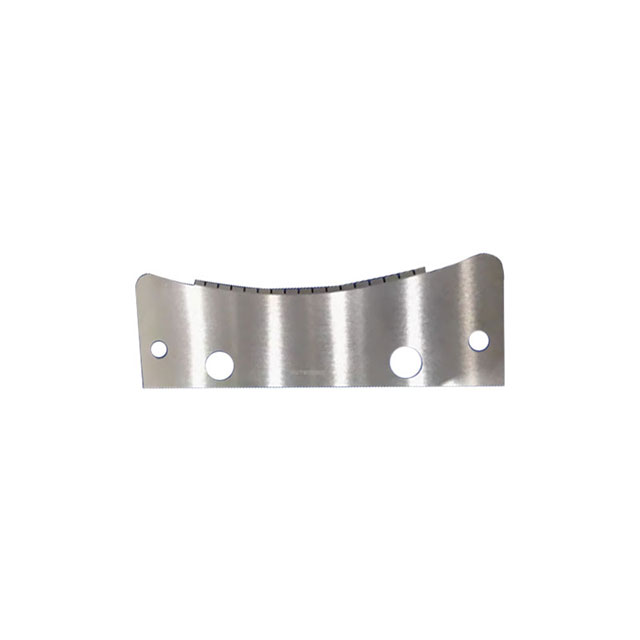

Design: The double-sided blade design allows for reversible use, extending blade life; the three-hole positioning system enhances mounting stability.

Main Applications

Film Slitting: Suitable for medium- and low-speed slitting equipment for BOPP/CPP films, aluminum foil composites, and other applications.

Paper Processing: Suitable for paper processing applications such as roll paper slitting and label die-cutting.

Other Applications: Including non-woven fabric slitting (medical/filtration materials), lithium battery separator slitting, and more.

Selection should be based on material hardness, equipment specifications, and cutting requirements (such as thickness and diameter).