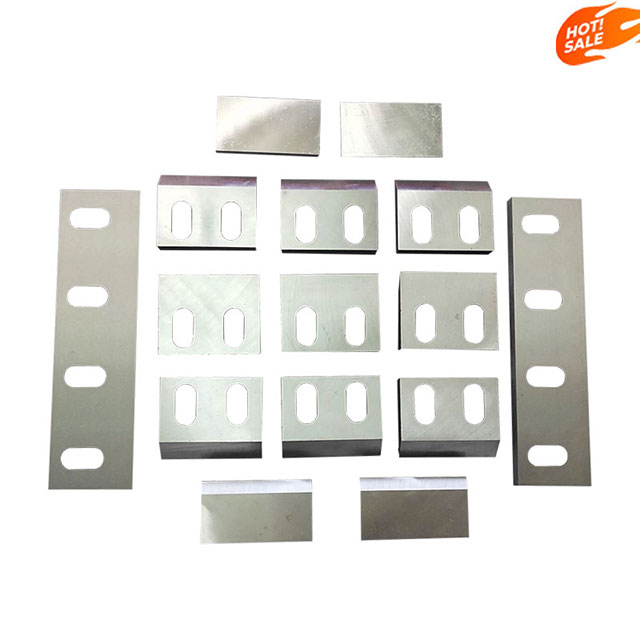

Flat Blade

The blade has a smooth, flat edge and is bolted to the blade shaft. It is suitable for cutting plastic blocks with regular shapes and uniform textures.

The operating principle relies on the impact force generated by the rotating blade shaft to directly cut the material, achieving high efficiency and low cost.

Serrated Blade

The blade has a serrated edge, which uses rotation to tear and shred tough plastics (such as films and fibers).

The serrated design reduces the risk of material entanglement and is suitable for processing highly ductile waste.

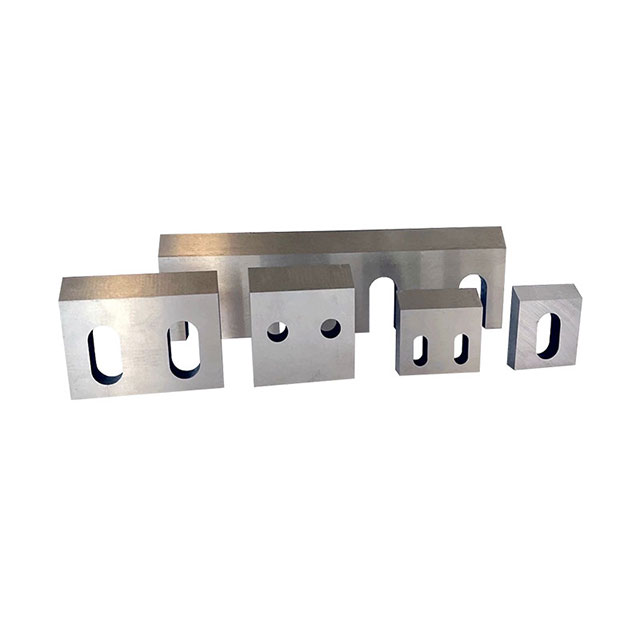

Hook Blade

The blade has a hook-shaped edge, which uses rotational force to grab and pull irregular plastic waste (such as plastic casings with attached electrical wires).

The hook-shaped structure effectively eliminates entanglement, but requires high blade strength and wear resistance.

Material Features

Carbide: High hardness and strong wear resistance make it suitable for crushing hard materials (such as metals and ores), with a long service life.

High-Speed Steel: Excellent hardness and toughness, high cost-effectiveness, and suitable for crushing conventional materials, but with slightly lower wear resistance.

Alloy Steel: Offers balanced overall performance, adaptable to different material requirements through alloy formulations, and mature manufacturing processes.

Combining different blades can improve pulverizing efficiency. For example, when processing high-fiber materials, a dual-shaft differential shear blade or a spiral pulverizer blade assembly can reduce entanglement and jamming.