Cutting Efficiency

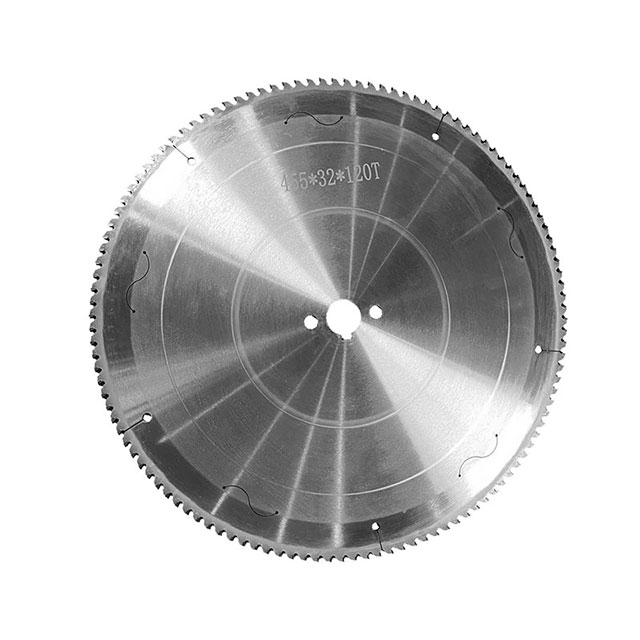

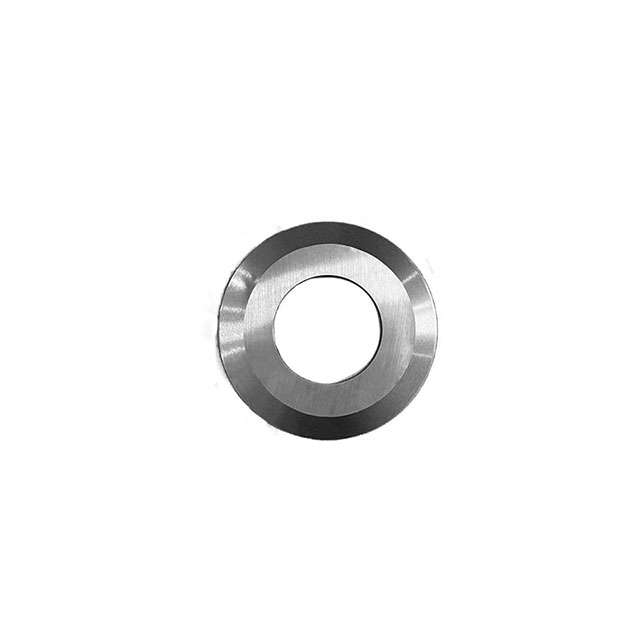

The circular blade utilizes a combination of shearing and extrusion, making it suitable for slitting materials thicker than 100μm and particularly well-suited for handling thicker materials (up to 10mm per layer). Its non-tangential slitting technology improves cutting accuracy and reduces material waste.

Durability

Made of high-hardness materials (such as tungsten steel), achieving a hardness of 89-93HRA, and precision manufacturing, it boasts a service life 3-5 times longer than traditional circular blades, significantly reducing blade change frequency. It maintains stable cutting performance even in high-temperature environments.

Applications

Widely used in the textile, leather, plastic, and packaging industries, such as cutting suit fabric, blanking automotive seat leather, and slitting medical non-woven fabrics. It is also used in the food industry for precision slitting of materials such as pastries and films, featuring low cutting resistance and high wear resistance.