Sugarcane Peeling Machine Blade Replacement and Adjustment Guide

A sugarcane peeling machine is an indispensable piece of equipment in the sugarcane processing process. Its core component, the blade, will need to be replaced due to wear after a period of use. This article will provide a detailed explanation of the sugarcane peeling machine blade replacement process, as well as the adjustment of the blade and machine maintenance steps.

I. Sugarcane Peeling Machine Blade Replacement Steps

- Preparation: First, ensure the sugarcane peeling machine is powered off and in a safe condition. Prepare the necessary tools, such as screwdrivers and wrenches, and ensure the new blade matches the machine model.

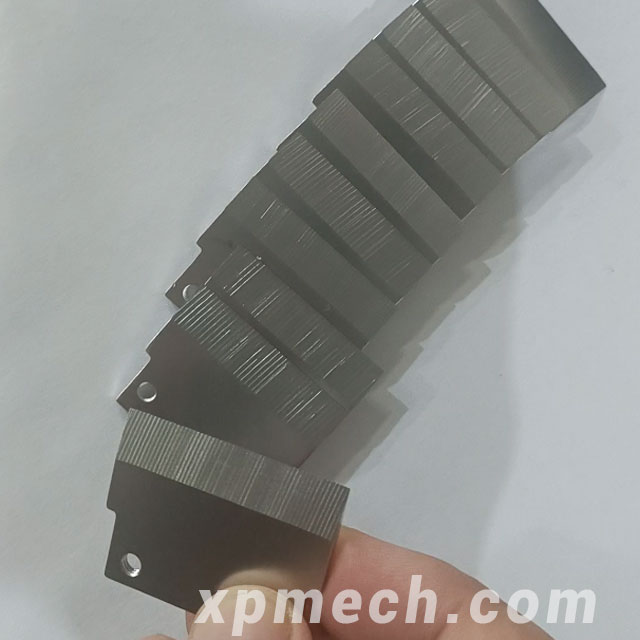

- Removing the Old Blade: Locate the blade’s fixing position, usually secured to the machine with screws or clips. Using appropriate tools, such as screwdrivers or wrenches, gently loosen the fixing parts and remove the old blade.

- Installing the New Blade: Align the new blade with its original position, ensuring a secure installation. Use screws or clips to secure the new blade to the machine. Note that during installation, ensure the blade is correctly positioned to avoid affecting the peeling effect or creating a safety hazard.

- Test Run: Connect the power supply and start the sugarcane peeler for a no-load test. Observe whether the new blades work in harmony with other parts of the machine, and whether there are any abnormal noises or vibrations. If any abnormality is found, stop the machine immediately for inspection and adjustment.

II. Sugarcane Blade Adjustment Method

Adjusting the sugarcane blade mainly involves adjusting the depth of peeling. If the peeling is too deep, it may waste sugarcane flesh; if the peeling is too shallow, the sugarcane peel may not be completely removed. Adjustment can be achieved by loosening the screws securing the blades and fine-tuning the blade position. After adjustment, remember to tighten the screws and conduct an actual peeling test to verify the effect.

III. Detailed Sugarcane Peeler Maintenance Steps

- Regular Inspection: Regularly inspect the sugarcane peeler, including key components such as the blades, motor, and transmission system. Timely detection and resolution of potential problems can extend the equipment’s lifespan.

- Cleaning and Maintenance: During use, sugarcane juice and residue may adhere to the machine. Regularly clean with detergent and a soft cloth to keep the equipment clean and hygienic. Meanwhile, regular maintenance and sharpening of the blades are essential to ensure effective peeling.

- Repair and Replacement: If any equipment malfunctions or damaged parts are found, contact a professional repair technician immediately for repair or replacement. Avoid attempting disassembly or repair yourself, as this could cause further damage or safety hazards.

In conclusion, replacing the sugarcane peeler blades, adjusting the blades, and maintaining the equipment are all crucial aspects of ensuring the normal operation of the sugarcane peeler and extending its service life.