Customization Process for Circular Blades

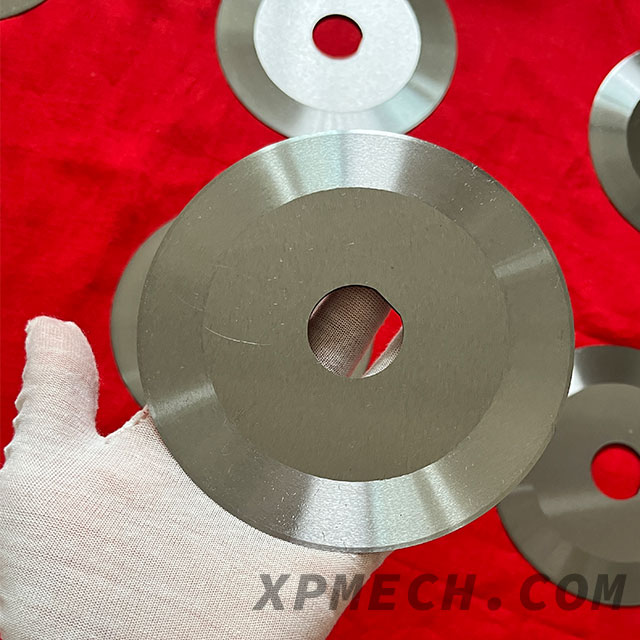

Circular blades, as a type of cutting tool, have many names depending on their application, shape, and category.

For example: small circular slitting blade, large circular cutting table blade, circular saw blade, pneumatic slitting blade, half-cutting blade, etc.

Besides standard sizes stocked in the factory, customized circular blades require the following process:

Material Selection – Selecting and casting materials according to requirements to increase material density.

Annealing – Allowing for rapid hardening to facilitate finishing.

Finishing – Primarily shaping the blank.

Quenching – Increasing the hardness of the shaped product.

Heating – Prolonged heat treatment to increase wear resistance.

Grinding – Grinding the product to improve precision, gloss, and parallelism.

Inspection – Rejecting substandard products from the market.

Packaging – Different packaging is used for different products.

Finished Product – Awaiting shipment.

If you have any questions about custom blades, please feel free to contact us!