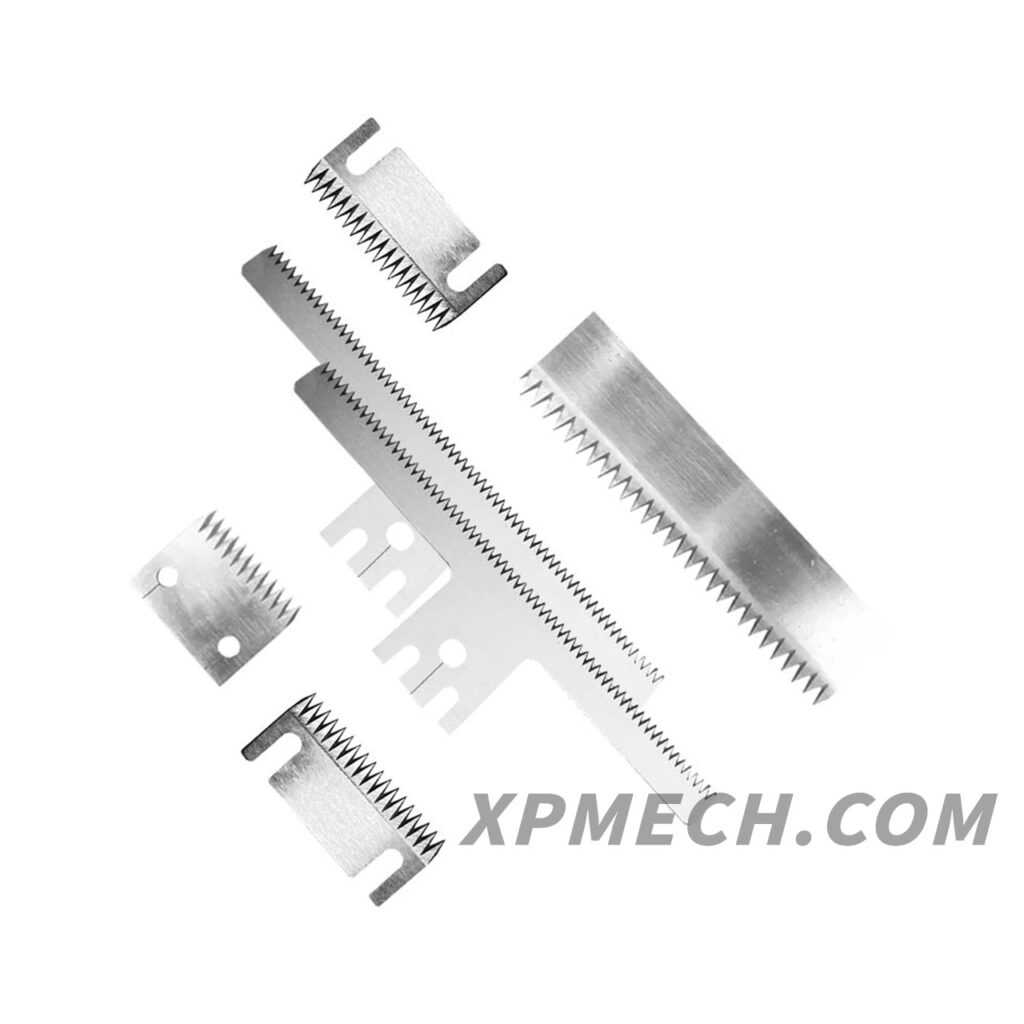

Carton Sealer Spur Blade Maintenance

- Daily Cleaning

After each use, use a soft cloth or brush to remove glue and paper debris from the spur blade surface. Stubborn stains can be removed with an alcohol wipe (75% alcohol concentration is recommended). Avoid using corrosive solvents. Cleaning frequency is recommended every 8 hours, or every 4 hours for continuous operation.

- Lubrication and Maintenance

Spur blade bearings and rotating parts require regular lubrication. Lithium-based grease (NLGI Grade 2) is recommended, applied approximately 3-5 grams monthly. Over-lubrication may attract dust and accelerate wear.

- Wear Inspection

Spur blade blunting criteria: When a notch exceeding 0.5mm appears on the blade edge (measured with a vernier caliper), or the tape cut rate falls below 90% (no tape cut at least once in 10 tests), immediate maintenance or replacement is required.

II. Carton Sealer Spur Blade Replacement Procedure

- Preparation

- Turn off the power and unplug the power cord to ensure safety.

- Prepare a serrated blade of the same model (common models include FM-9 and FM-12; please refer to the equipment manual for confirmation).

- Removing the Old Serrated Blade

- Loosen the retaining screws (usually M4 or M5) with an Allen wrench.

- Gently tap both ends of the blade shaft and slowly remove the old blade to avoid damaging the blade holder.

- Installing the New Serrated Blade

- Align the new blade with the slot, ensuring the blade’s direction aligns with the tape’s direction.

- Tighten the screws diagonally, maintaining a torque of 0.8-1.2 N·m.

- Commissioning and Testing

Run the machine at no load for 3-5 minutes and observe for any unusual noises. Then, test the cutting performance with a waste cardboard box and adjust the pressure screw until the tape is cut smoothly and without burrs.

III. Additional Tips for Extending Serrated Blade Life

- Avoid cutting thick materials (such as double-layer corrugated paper with metal edges). The recommended single-cut thickness is ≤8mm.

- Check the toolholder balance weekly. If deflection exceeds 0.3mm, calibrate using a dial indicator.

- Store spare blades in a dry environment to prevent rust.

Through proper maintenance and accurate replacement, the life of the cutter blades can be extended to 6-12 months (depending on workload), significantly reducing the risk of equipment downtime.