Bottle Cap Ring Cutter Blades – How to Choose the Right Blade

Blade Material

Ring cutter blades are generally made of materials such as high-speed steel, carbide, and ceramic. High-speed steel blades are widely used, primarily due to their low price and wide applicability, making them suitable for cutting soft materials. Carbide blades are more expensive, but they offer strong wear resistance and are suitable for high-intensity cutting operations. Ceramic blades, on the other hand, offer the longest service life, but are more expensive and have a narrower application range.

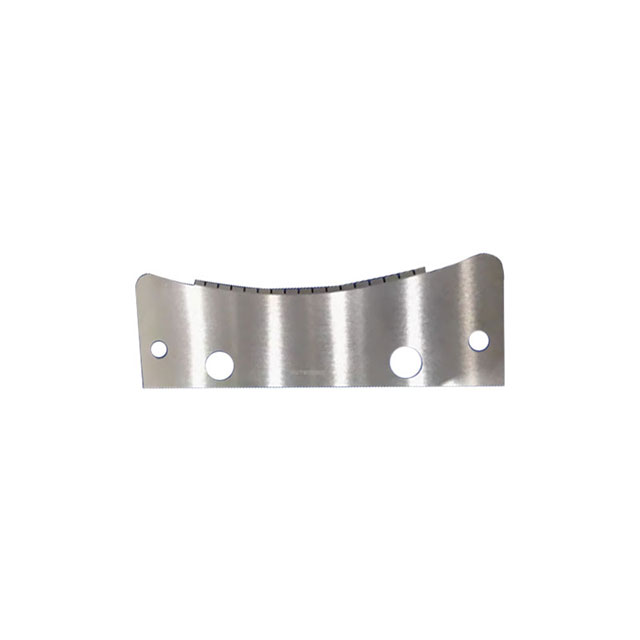

Cutting Edge Shape

Ring cutter blades come in a variety of cutting edge shapes, including straight, beveled, and toothed blades. Different cutting edge shapes are suitable for different materials. Straight-edge blades are recommended for soft materials, while toothed blades are recommended for hard materials. Beveled-edge blades are a good choice for materials with smooth surfaces.

Blade Hardness

Blade hardness is a key factor in cutting performance. The harder the blade, the greater the wear resistance and the longer the service life. When selecting a blade, choose the appropriate hardness based on your specific needs. Blades that are too soft can easily damage the cutting edge and significantly shorten their lifespan. Blades that are too hard can result in high cutting forces, break easily, and be difficult to use.

How to Choose the Right Ring Slitter Blade?

Selecting the right ring slitter blade requires a comprehensive consideration of both actual needs and the material type. The blade material, cutting edge shape, and hardness should be determined based on factors such as the material’s hardness, density, viscosity, and fiber distribution.

While using the blade, proper maintenance is essential. Clean the cutting area promptly to prevent residue that can affect cutting results. Regular inspection and oiling of the blade are also essential to extend its lifespan.

Choosing the right ring slitter blade can improve cutting efficiency and quality while reducing production costs. We hope this article will help you better select the right ring slitter blade for your needs, improve production efficiency, and achieve better cutting results. If you have any further questions or inquiries, please feel free to contact us.