A Complete Guide to Using Circular Blades

- Secure Installation is the First Step

Want a circular blade to work smoothly? The key is securing it. Unlike straight-edged tools, circular blades require a special chuck or flange for securement, using a center hole to ensure rotational balance. During installation, pay attention to three key points: check the blade’s perpendicularity to the axis, tighten the fixing screws evenly, and finally, tap the blade gently to listen for a sharp click to confirm proper fit. Remember, a wobbling blade not only affects accuracy but can also cause a “flying saucer” motion and cause an accident.

2.The Art and Science of Grinding

When a circular blade starts to slack off, proper grinding can give it a new lease of life:

Angle Control: Maintain a 15-20 degree tilt angle and apply pressure at a steady speed, like pumping air into a bicycle tire.

Direction Selection: Always grind along the arc of the cutting edge; grinding against it will easily create burrs.

Pressure Control: Think of yourself polishing glass; excessive pressure can damage the microstructure of the cutting edge.

Cooling Technique: Dip in water every 30 seconds to cool the blade and prevent the metal from annealing and softening.

3.The Secret Rituals of the Whetstone

That humble round whetstone is actually a “Transformer”:

The coarse grind (200 grit) is used to repair severe defects, like an eraser erasing work errors.

The fine grind (1000 grit) is used for fine finishing, like giving the blade a spa treatment.

Soak the grindstone for 10 minutes before use to hydrate it, and keep it moist while working.

Finally, smooth the blade over a strip of leather, much like a barber gives a razor a few final strokes.

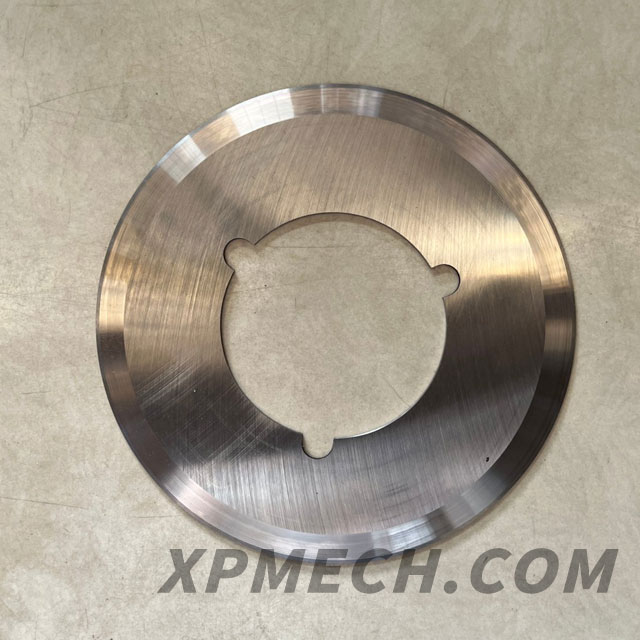

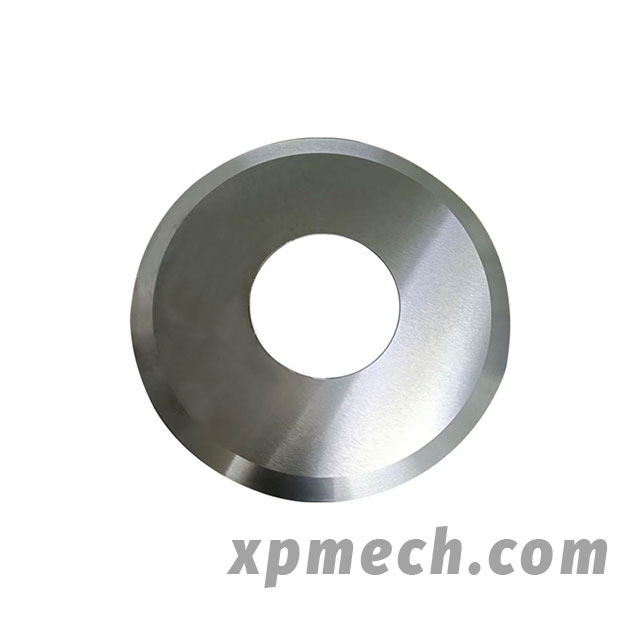

For those who need to frequently change blades, we stock sharp steel circular blades with a center hole design that’s compatible with most slitting equipment. They offer both wear resistance and cutting efficiency, making them particularly suitable for continuous operation environments like slitting and cutting machines.

For business owners looking to learn more about related products, why not visit iCaigou? iCaigou offers comprehensive information and can meet your numerous needs!