How to Solve Problems with Tape Cutting on a Carton Sealing Machine

Problems with tape cutting on a carton sealing machine can be caused by various reasons, requiring targeted solutions.

First, check the blade’s sharpness. If the blade is dull, it will have difficulty cutting the tape smoothly, so consider replacing it with a new blade. Also, check if the tape is installed correctly, such as whether it’s wound too tightly or too loosely on the reel, or if its position is off-center. Adjust the tape installation accordingly. Additionally, check for debris clogging the cutter; cleaning it will allow the cutter to work properly. There might also be a problem with the carton sealing machine’s transmission components, such as a loose belt or worn gears. This requires professional inspection of the transmission system. Finally, confirm that the carton sealing machine’s operating parameters are set appropriately, such as the cutting force. If not, adjust them accordingly.

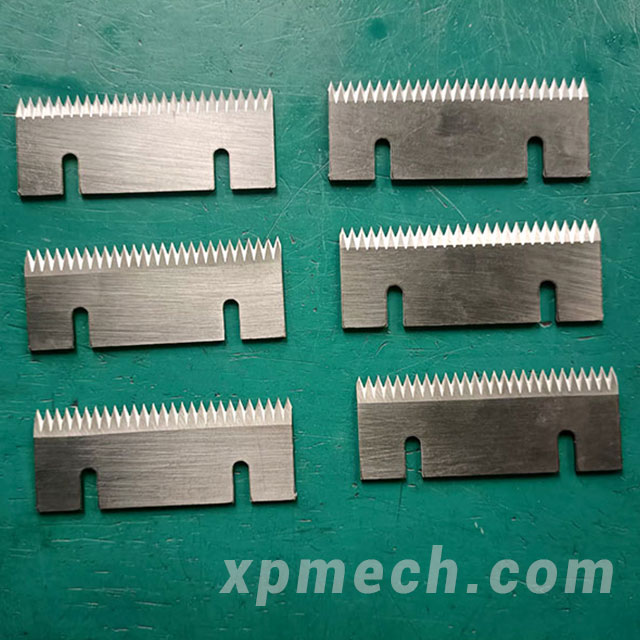

- Check the blade: A dull blade directly affects the tape cutting effect. Regularly check the blade’s condition, and replace it promptly when cutting becomes difficult. New blades ensure smooth cutting and improve sealing efficiency. Different types of carton sealing machines may require different blade specifications; select the appropriate model for replacement.

- Check Tape Installation: Improper tape installation is a common problem. If the tape is wound too tightly, it will increase cutting difficulty; if it’s too loose, it may cause the tape to deviate. Correct installation allows the tape to be fed steadily during the sealing process, facilitating accurate cutting by the cutter. Ensure the tape is neatly arranged on the reel without twisting.

- Clean the Cutter Area: Debris clogging the cutter is a cause of poor cutting. Dust, paper scraps, etc., can accumulate around the cutter, hindering its movement. Regularly cleaning the cutter and keeping it clean will ensure proper functioning. Use a clean cloth or tool to carefully clean the cutter’s slits and surface.

- Inspect Transmission Components: Transmission component malfunctions can also have an impact. A loose belt will result in insufficient power transmission, and worn gears will lead to inaccurate transmission. During professional inspection, the belt tension should be carefully checked, and adjusted or replaced as necessary. Worn gears should be replaced promptly to ensure the normal operation of the transmission system.

- Confirm Operating Parameters: Setting the operating parameters of the carton sealing machine is crucial. Inappropriate cutting force and other parameters may lead to poor cutting. Adjust cutting force and other parameters appropriately based on the tape’s material and thickness. Through multiple tests, find the most suitable parameter settings for the current tape to achieve a smooth cut.