The material of the circular blade determines cutting quality: high-speed steel is suitable for soft rubber, while carbide is more wear-resistant and durable. Regular blade maintenance, precise adjustment of cutting parameters, and matching of specifications ensure efficient and safe cutting—choosing the right blade means choosing the right production efficiency.

In this article, we will explore how to choose a circular blade for cutting rubber?

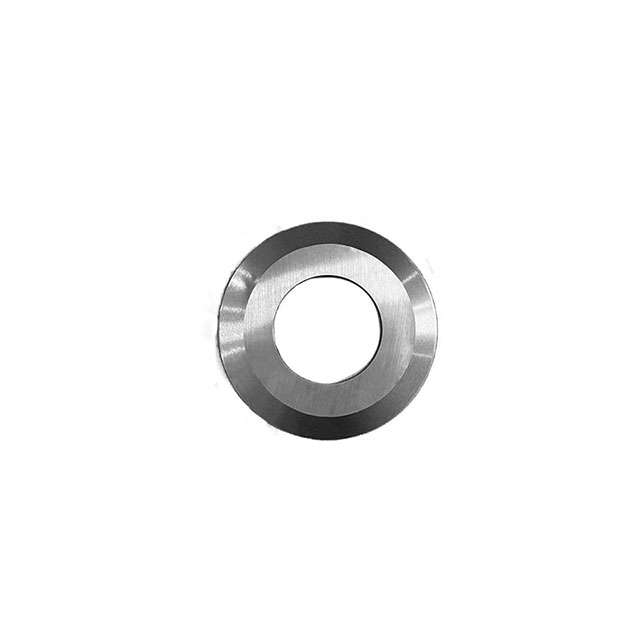

Rubber slitting machines are indispensable equipment in the rubber processing industry. Their primary function is to cut large-format rubber materials into the desired strips or sheets. As a key cutting tool, circular blades play a crucial role in this process. Many people have misconceptions about circular blades for rubber slitting machines. This article will address these common misconceptions and help readers better understand the characteristics and precautions of circular blades.

Many people believe that the material of a circular blade is unimportant, as long as the blade can cut. In fact, the material of a circular blade directly affects the quality and efficiency of cutting. Common circular blade materials include high-speed steel, carbide, and ceramic. High-speed steel blades have excellent toughness and wear resistance, making them suitable for cutting softer rubber materials. Carbide blades are more wear-resistant and suitable for cutting harder rubber. Ceramic blades, while sharper, are relatively fragile and require special care when handling. Choosing the right blade material is key to ensuring effective cutting.

Some people believe that circular blades don’t require regular maintenance and replacement during use. In fact, blade maintenance and replacement are crucial for ensuring the proper operation of rubber slitting machines. Blade sharpness gradually decreases over time, affecting cutting performance and even causing tearing or waste of the rubber material. Regularly checking blade wear and replacing it appropriately based on frequency of use are crucial measures to maintain efficient equipment operation.

Furthermore, some users misunderstand the cutting speed and depth of circular blades. They often believe that increasing the cutting speed and depth will improve production efficiency. In reality, the cutting speed and depth need to be adjusted based on the characteristics of the rubber material. Excessive cutting speeds can cause the blade to overheat, shortening its lifespan; excessive cutting depths can easily damage the material. When setting cutting parameters, consider the material’s hardness, thickness, and blade durability to find a suitable cutting solution.

Furthermore, many people assume that the lifespan of a circular blade is solely dependent on the blade material, overlooking the impact of the cutting process and environment. The cutting process includes factors such as the feed angle, cutting speed, and feed rate, all of which affect blade wear. The cutting environment also affects the blade’s lifespan. For example, high or low humidity can affect blade performance. Maintaining a good cutting environment can extend blade life.

Many people tend to overlook the blade’s specifications and size when purchasing circular blades. They assume that as long as the blade fits the slitting machine, it’s fine. However, blade specifications and size have a direct impact on cutting performance. Different rubber slitting machine models require different blade specifications. Using an inappropriate blade can result in uneven cutting and even damage the equipment. When purchasing circular blades, be sure to refer to the equipment manual to select the appropriate specifications and size.

Furthermore, some users believe that the higher the price of a circular blade, the better. They often pursue higher-priced products, believing this will yield better cutting results. However, a blade’s price doesn’t necessarily reflect its performance. There are many cost-effective blades on the market that can meet general cutting needs. When purchasing, it is recommended to consider both actual usage needs and budget to select the appropriate product.

It is important to note that safe operation is also crucial when using a rubber slitting machine. Circular blades can create flying chips and other hazards during cutting. Therefore, always wear protective equipment and keep your work area clean to avoid accidents. Follow the equipment’s operating manual to ensure safe operation.

The circular blades used in rubber slitting machines play a crucial role in rubber processing. Understanding circular blade material selection, maintenance and replacement, cutting parameters, cutting environment, specifications, pricing, and safe operation will help users better utilize this tool and improve production efficiency and product quality. If you have further questions about circular blade selection and use, please feel free to send us a message to discuss.