Sticking on the sealing blades is a common problem when using automatic packaging machines. It can lead to poor packaging, inefficiency, and even equipment damage. The following details several ways to address this issue.

Cleaning and Maintenance

- Regular Cleaning: Regularly clean the sealing blades and the area around them from debris and residual tape to maintain a clean and tidy working environment. Use a dedicated cleaner or alcohol to remove oil and glue stains.

- Maintenance: Perform regular maintenance according to the equipment manual, such as lubrication and tightening loose parts, to ensure the equipment is in good working condition.

Adjusting Operating Parameters

- Adjusting the Temperature: Appropriately adjust the sealing blade temperature based on the packaging material and tape type. Excessively high temperatures may cause the tape to melt and stick, while excessively low temperatures may result in a weak seal.

- Adjusting the Pressure: Properly adjust the pressure of the sealing blade on the tape to ensure a high-quality seal while avoiding excessive pressure that may cause the tape to stick.

- Speed Adjustment: While ensuring stable equipment operation, adjust the strapping speed appropriately to reduce friction and heat accumulation between the tape and the sealing blade.

Accessory Replacement

- Tape Replacement: Select high-quality tape with moderate viscosity to avoid sticking caused by tape quality issues. Also, regularly inspect and replace any aging tape to ensure it is in good condition.

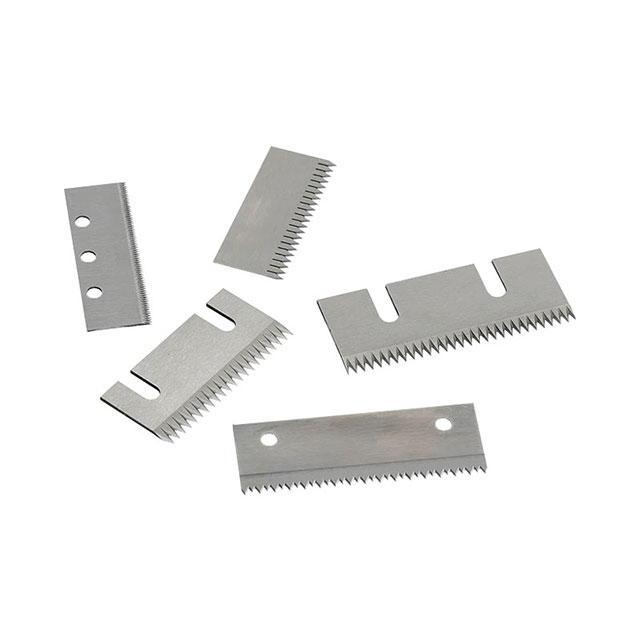

- Sealing Blade Replacement: If the sealing blade becomes severely worn or chipped due to long-term use, replace it promptly to ensure sealing quality and performance.

Other Precautions

- Operating Instructions: Strictly follow the equipment’s operating procedures to avoid sticking caused by misoperation. Additionally, provide regular operator training to improve their skills and problem-solving abilities.

- Equipment Selection: When purchasing an automatic strapping machine, select the appropriate model and configuration based on your actual needs to ensure it meets production requirements and offers high stability and reliability.

In summary, resolving the gluing issue with the sealing blades of automatic balers requires a multi-faceted approach, including cleaning and maintenance, adjusting operating parameters, replacing accessories, and adhering to operating procedures. Only by taking these combined measures can the gluing issue be effectively resolved and the efficiency and productivity of the baler improved.