Typically manufactured from alloy tool steel or cold-work die steel, the surface undergoes a multi-layered weld overlay process for enhanced hardness and wear resistance. The blades are designed with a flat surface, and a pusher mechanism pushes the material toward the blades for tearing, squeezing, and shearing. This structure provides stable performance when handling brittle materials such as wood and plastic. Its large shearing area makes it suitable for handling bulk materials and quickly shredding large solid waste (such as scrap furniture and metal briquettes). It generates greater shear force during the shredding process, improving operational efficiency.

High Durability

Constructed from high-strength alloy steel, the surface undergoes an optimized heat treatment process, achieving a hardness of HRC58-62 (referring to metal shredder blade standards). This exceptional wear resistance allows for continuous shredding of high-strength materials (such as tree stumps and scrap metal) and a long service life.

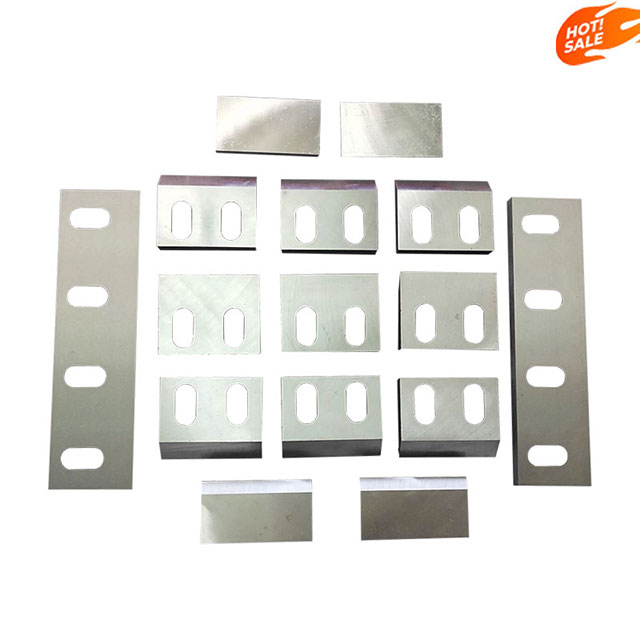

Adaptable Modular Design

Some models offer flexible adjustment of blade thickness and number, allowing you to change blade combinations based on different material characteristics. For example, when handling hollow materials, a presser can be added to improve feeding efficiency, meeting diverse operational needs.