Where to Adjust the Cutting Blade Speed on a Packaging Machine

On a packaging machine, adjusting the cutting blade speed usually refers to adjusting the drive speed or frequency of the cutting blades to adapt to the needs of different packaging materials, thicknesses, or production cycles. The specific adjustment location and method vary depending on the type of packaging machine, but mainly focus on the following aspects:

- Adjusting the Speed Level via the Control Panel

Many modern packaging machines (such as automatic filling machines and granule packaging machines) offer three speed settings: fast, medium, and slow. Users can directly select these using buttons or knobs on the control panel:

Fast: Suitable for thin, easily cut materials or high-speed production scenarios.

Medium: A general mode, balancing speed and precision.

Slow: Suitable for thick films, high-precision requirements, or easily deformable materials, ensuring a clean cut.

For example, the operating instructions for an automatic packaging machine clearly state: “Adjust the speed to three levels: fast, medium, and slow.”

- Adjusting the air pressure or motor parameters of the drive mechanism. For cutting systems driven by pneumatic or servo motors, speed adjustment may involve:

Air pressure adjustment: Decreasing or increasing the air pressure via the pressure regulating valve on the side of the machine controls the movement speed of the moving blade.

Motor parameters: On equipment with frequency converter control, the motor operating frequency (Hz) or acceleration/deceleration time can be modified via the control panel.

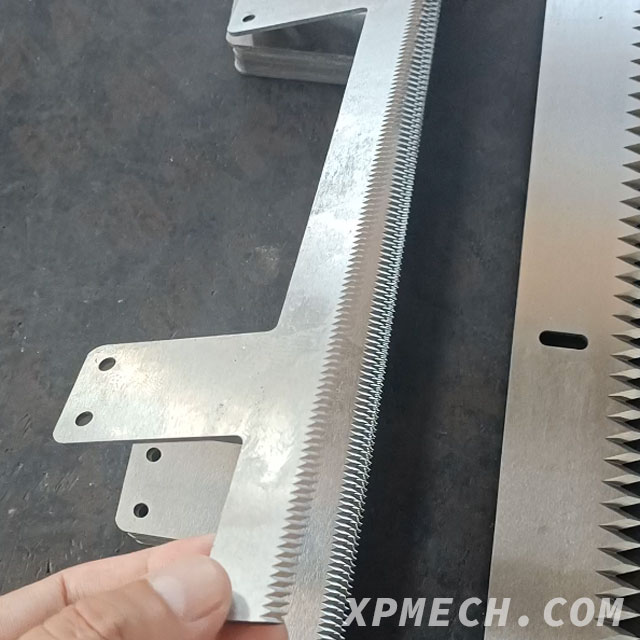

- Adjusting the mechanical transmission mechanism. In traditional mechanical packaging machines, the blade speed is often driven by a crank-connecting rod mechanism or a cam. Adjustment methods include:

Replacing the pulley: Replacing pulleys of different diameters changes the transmission ratio.

Adjusting the cam position: Changing the cam profile or mounting angle affects the blade’s operating cycle.

- Adjusting the Clutch Clearance: In pillow-type packaging machines, the engagement time of the cutting clutch affects the blade’s operating frequency.

- Adjusting in Sync with Packaging Speed: In fully automated production lines, the cutting speed is often synchronized with the conveyor belt speed. To change the cutting speed, you typically need to:

Adjust the output frequency of the conveyor belt inverter.

Modify the blade’s timing parameters in the PLC program (requires professional personnel).

Common Precautions:

Safety First: Always disconnect the power and release air pressure before adjustment to prevent accidental start-up.

Materials Matched: Thick films or high-toughness materials require slower speeds to ensure a clean cut; thin films can be appropriately speeded up to improve efficiency.

Blade Condition: Before adjusting the speed, ensure the blade is sharp and the clearance is appropriate (generally around 0.05mm); otherwise, even with the correct speed, it may not be able to cut through.

If you are unsure about the adjustment method for a specific machine model, it is recommended to consult the equipment operation manual or contact the manufacturer’s technical support.