Toothed Blade Introduction and Selection

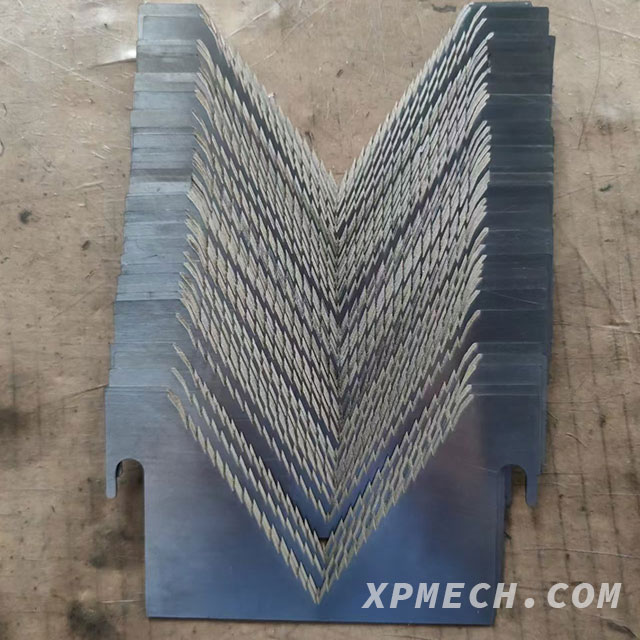

Toothed blades are industrial cutting tools with a serrated structure, mainly used for material slitting and processing in industries such as paper, steel metallurgy, rubber and plastics, and electronics. The serrated design improves cutting accuracy and efficiency.

Specifications and Materials

Core Parameters:

Size Range: Common sizes include 54×25×1.5mm (center hole distance 40mm), 63×25×1.5mm, etc. Non-standard customization is supported.

Surface Finish: After machining, the surface roughness reaches Ra0.7–1.4μm, meeting high-precision cutting requirements (such as crusher blades).

Hardness and Temperature Resistance: Material hardness 86–93HRA, stable performance at 500℃, and maintaining high hardness at 1000℃.

Mainstream Materials:

Alloy Steel: SKD11, Cr12Mov, H13, balancing wear resistance and impact resistance. Hard alloys: Tungsten carbide (tungsten carbide-based), such as YG and YT, suitable for ultra-thin or high-load applications.

Application Scenarios

Industrial Sector:

Paper/Packaging: Slitting circular blades, carton sealing machine blades (e.g., tape cutters), achieving burr-free slitting.

Metallurgy/Machinery: Rolling mill blades, shearing machine blades, for processing sheet metal and profiles.

Electronics/Precision Machining: Circuit board cutting blades, V-CUT blades, with micron-level precision for hole diameter and tooth profile matching.

Special Scenarios:

Gear Machining: Gear cutting cutters using generating cutting technology, achieving a precision of 1.6μm (DIN AAA standard).

Landscape/Agriculture: Lawn mower blades (e.g., 47cm heavy-duty blades), increasing the efficiency of cutting fiber materials by 30%. Purchase Guide and Recommendations

Key Selection Points:

Material Matching: Choose alloy steel (SKD11) for soft materials (such as plastic), and tungsten steel for hard materials (metals).

Needle Design: Fully serrated blades (such as Spyderco Para2) are suitable for ropes/cardboard, while flat blades have wider versatility.

Parameter Verification: Confirm the bore diameter, number of teeth (e.g., 190-tooth case), and equipment compatibility.