How to sharpen circular cutting blades?

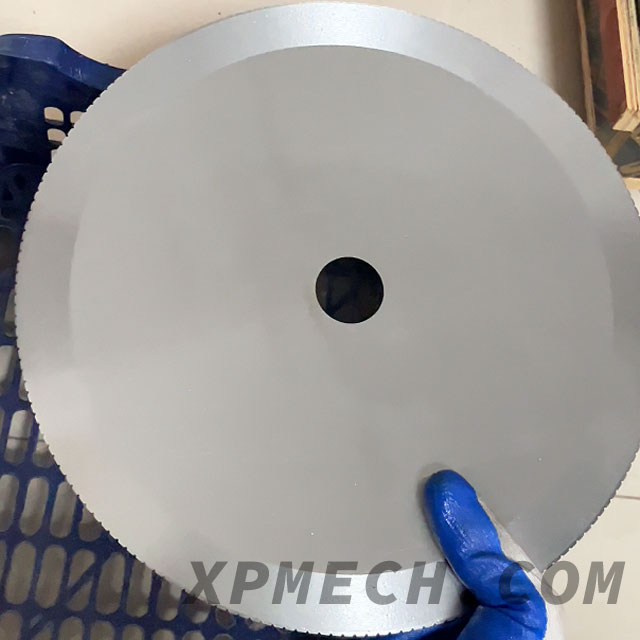

Circular cutting blades, also known as ring-shaped cutting blades, are mainly used for cutting snacks, printing paper, plastic film, gold, silver foil, aluminum foil, copper foil, etc. They are designed to minimize cutting friction and have high wear resistance. Circular cutting blades are widely used in ceramics, printing equipment, papermaking, cardboard boxes, forestry, plastics, food processing machinery, textiles, home appliances, rubber and plastics machinery, aluminum foil, metallized films, cigarettes, tobacco machinery, packaging products, plastic film, electronics, cables, shipbuilding, chemical fibers, fiberglass, textiles, feed, paper core tubes, forestry, woodworking equipment, plastic crushing, side sealing, center sealing machinery, bottom sealing plastic bag making machines, log processing, food packaging materials, papermaking aluminum foil cutting, metallurgical electromechanical engineering, traditional Chinese medicine, plastics, and many other industries. Circular cutting blades are generally durable and have excellent machinability, but they will inevitably wear down over time. The extent of this wear depends on several key factors.

- Manufacturing Process

The manufacturing process of circular cutting blades prioritizes hardness and wear resistance, but also minimizes ductility. Hardness and toughness are inversely related, which is an aspect that must be improved. For high-purity graphite circular cutting blades, raw materials with better ductility can be selected.

- Surface Coating

Diamond-coated circular cutting blades possess advantages such as high hardness, good wear resistance, and low friction resistance, making them the most ideal manufacturing process currently. However, the manufacturing cost is high, and the technology in this area is not yet fully developed in my country. High-purity graphite-coated circular cutting blades are more widely used and economical.

Therefore, to reduce the wear of circular cutting blades, one can consider both the material and the coating.

How to repair worn circular cutting blades?

- Open the blade from the flat surface and re-grind, ensuring a bright, unblunt edge. Then re-grind the sides, paying attention to flatness.

- If the blade is found to be skewed after grinding, adjust the grinding pressure and appropriately change the speed on the slightly thicker side.

- Regularly check the precision of the grinding plate and calibrate the platen.

- During the regrinding process, if the ambient temperature of the workpiece exceeds 40-50°C, stop for a certain period and allow it to cool before continuing, as overheating will affect the precision of the blade. Regrinding the circular blade will maintain its performance characteristics, allowing for more precise cutting of the workpiece and ensuring the success of the entire cutting process.

- After regrinding, the circular blade should be coated with a rust inhibitor to prevent corrosion.